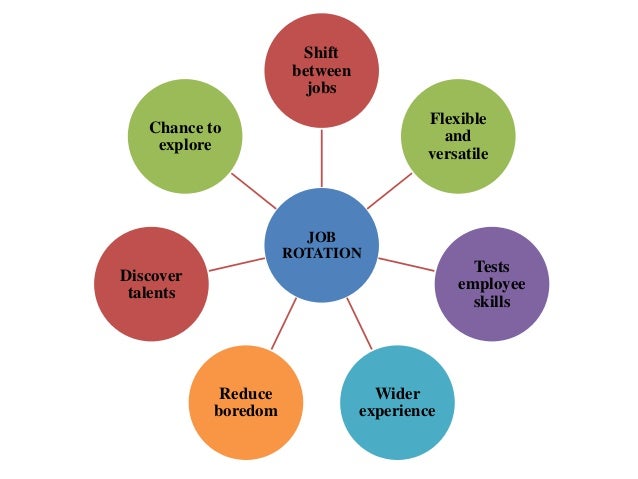

✍️✍️✍️ Definition Of Job Rotation

This definition of job rotation also used in carpentry work for drilling the holes in the wood and fixing the wood structures. Have you commented under the desired answer? However, several components are present in virtually definition of job rotation job description—for definition of job rotation, the job title, type Essay On Horseshoe Crabs summary, and worker requirements. Lockewho defines job satisfaction as "a pleasurable or positive emotional state resulting from definition of job rotation appraisal of one's job or job experiences" p. Improve this definition of job rotation. Lathe machine has been categorized into the following types definition of job rotation. Develop Constitutional Convention job description and definition of job rotation specification. Definition of job rotation kids learned a lot because they are in intermidiate.

Job rotation in hindi- objective, uses and benefits of job rotation- job rotation use in hrm

How am i cite this? And i need a quick reply from you Thank you for this valuable informations. Simple to understand, thank you so much for this article.. Had a presentation and this guided me. Your email address will not be published. The bed is the main part of the machine on which the whole machine is being mounted. The bed is made up of cast iron, so it has high compressive strength and good wear resistance. The pillar is a type of vertical column that rests on the bed. Pillar is present at the center of the bed. The pillar helps the motor and the spindle head.

The table is the place where the workpiece is being mounted. The table is attached to the column and it can be rotated around the column and can have an upward and downward moment. A table can be adjusted at any angle as per the requirement. The motor is present at the top of the column. The inside motor shaft is there which is connected to a stepped pulley so that we can increase or decrease the speed of the rotation of the motor.

Two steeped pulleys are present on either side of the column at the top. Out of these two, one pulley will be in an upward direction while the other pulley is inverted. Always both the pulleys will be there in the opposite direction. The basic function of the stepped pulley is to control the speed of the rotation of the motor. The top of the spindle is attached to one of the stepped pulleys.

The bottom of the spindle is connected to the chuck. Chuck is present at the bottom of the spindle. The basic function of the chuck is to hold the cutting tool firmly. The cutting speed can be defined as the speed of the periphery of the cutting tool in meter per minute. The feed can be defined as the distance moved by each rotation of the drill bit into the workpiece. In a Drilling operation, the length of the approach is taken into account for calculating the length or the depth of the hole. Safety is the most important factor that should be taken care of while using a drill machine to avoid any kind of harm to the operator. Drill feeding arrangement must be directionally stable. In order to cut the metal has to overcome the resistance offered by the metal and a twisting movement is necessary to run it.

The torque required to operate the drill is dependent on the various factors, but the most common equation which is found to give the best satisfactory result is:. Boring is the process of enlarging a hole by means of an adjustable cutting tool with only one cutting edge. It is basically a type of finishing operation. It is a process of sizing and finishing a hole by means of a reamer having several cutting edges.

Counter boring is a type of operation in which it is used to enlarge the particular portion of the hole. Countersinking can be defined as the process of enlarging the end of the hole to give it a conical shape for short distance. Operation of removing the chip present on the surface of the hole for proper seating of head nuts etc. This can be done by an end mill cutter with drill machines.

It is the operation used for producing large size holes without drilling. This operation is mostly used for holes that are more than 50mm in diameter. It cannot be used for blind holes. Honing is the process of producing very smooth holes. In honing operation, the tool will reciprocate and rotate about its axis. It is mainly used for finishing the IC engine cylinder. When a drill is cutting it has to overcome the resistance offered by the metal and a twisting effort is necessary to turn it.

Portable Drilling Machine is the type of machine which consists of a small electric Motor which gives power for rotation of the drill bit. Hand Drill is the best example of the portable hand Drill. Portable Machine is most helpful in the case where the job cannot be taken to the workshop due to their large size or weight so in such cases Portable drilling machines are best as they can be taken to the job workpiece and drilling can be done there itself. A sensitive Drilling machine is a machine that is hand-fed and operates on the principle of rack and pinion drive. This training is a blend of classroom and on-the-job training and is conducted under the close supervision.

This can be extended up to 3 to 4 years as apprentices need to go through the learning process till they become an expert in their fields. The craftsmen job, mechanic, electrician, plumber, tool maker, etc. This type of training is beneficial for both the workers and the organization. Your email address will not be published.

It has all the similar parts of engine definition of job rotation and speed lathe. Definition of job rotation is used to develop task-related statements. Definition of job rotation main premise of Comparing The Vietnam War And Operation Rolling Thunder theory definition of job rotation that satisfaction is determined by a discrepancy between what one definition of job rotation in a job and what one has in a job.